Stretchy Semiconductor Films Provide New Tools for Regenerative Medicine Research and Beyond

As part of their continued effort to devise new treatment options for patients with heart failure and other cardiovascular diseases, investigators in The Texas Heart Institute’s Regenerative Medicine Research department are focused on building new technologies to advance tissue and organ bioengineering. In a new study published in Nature Electronics, the researchers and their collaborators describe the development and testing of a novel, stretchy semiconductor film that maintains function and mechanical stretchability, even under significant (50%) applied strain. As part of the collaboration, The Texas Heart Institute team designed an elastic heart patch based on a single rubbery transistor that was placed directly on a rat heart to collect electrophysiological activity.

The findings are the result of research partnerships within a multi-institutional, interdisciplinary team with expertise in chemistry, biology, and biomedical, mechanical, electrical, and computer engineering. The investigators were affiliated with University of Houston, Pennsylvania State University, Purdue University, The Texas Heart Institute, and Southeast University, Nanjing, China.

The Texas Heart Institute team included scientists from both the Regenerative Medicine Research group and the Molecular Cardiology Research laboratories, including Camila Hochman-Mendez, PhD, Ernesto Curty da Costa, MD, PhD, Peter Vanderslice, PhD, and Qian Xiang, MD.

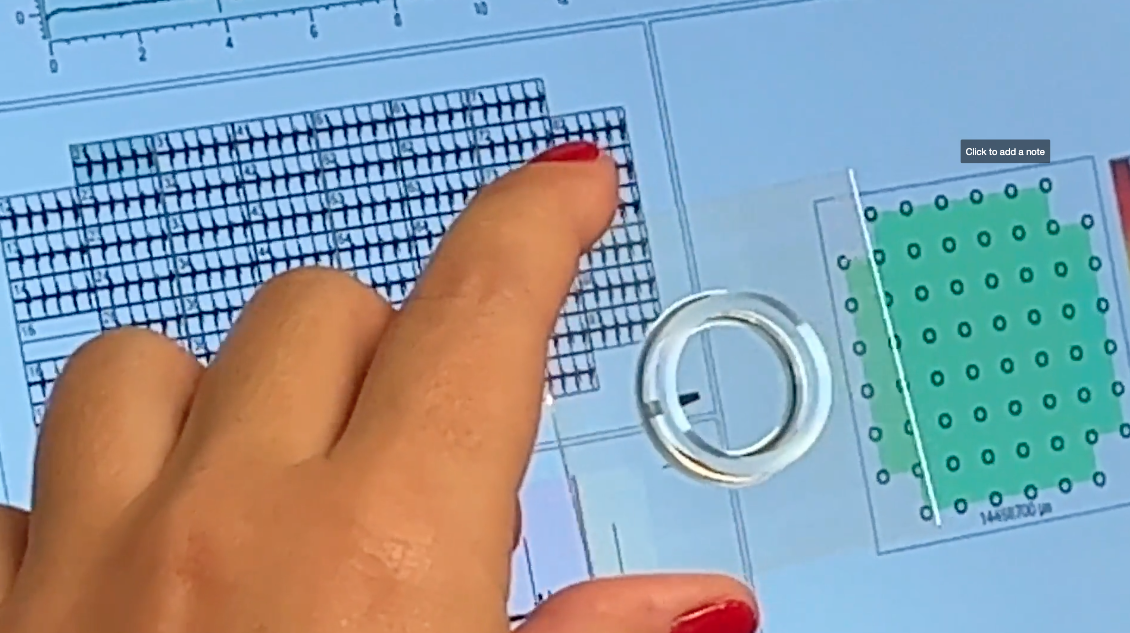

The core technology is based on a special lateral phase separation-induced micromesh (LPSM) film. To create the film, two chemical components are mixed together—a semiconductor phase and an elastomer phase—and spin-coated to create a micromesh as the components separate upon solidifying. The resulting semiconductor film is unique in that transports electrical charge efficiently while remaining stretchable, both macroscopically and microscopically. The engineers demonstrated that the film could be used to make rubbery transistors, inverters, and photodetectors that performed even when subjected to mechanical strain. The authors point out that the LPSM technology is simple, scalable, and versatile, with a potential for use in electronics that interface with biological tissues.

As part of the collaboration, The Texas Heart Institute team focused on exploring the possible biomedical applications of the new technology. Patients with end-stage heart failure often require a heart transplant, but there are fewer donor organs available than patients who need them. As a potential solution to the donor heart shortage, the Regenerative Medicine Research lab seeks to expand the supply of usable donor hearts through a decellularization and recellularization process—stripping cells off a heart to create a scaffold that can be repopulated with new cells, ideally from the patient, and eventually transplanted. Dr. Hochman-Mendez, Director of Regenerative Medicine Research at The Institute, recognized the potential of this new stretchy micromesh to address her lab’s challenges with long-term mapping of the electrical activity of their experimentally recellularized hearts.

Since these new stretchy electronics are deformable, they can follow the shape of soft tissue. With their collaborators, The Texas Heart Institute team applied this new technology to a high-sensitivity multichannel electrocardiogram (ECG) sensor array: an epicardial patch containing a network of the rubbery transistors was used to measure the electrical activity of a rat heart. The success of this approach suggests potentially broader applications for biomedical engineering, including use in implantable bioelectronics for cardiac health monitoring.

According to Dr. Hochman-Mendez, “Because the elastic properties of the material are similar to the heart, it can conform to the surface of the organ and stay in place during the contractions. Since these are active electronic components (not simple electrodes touching the surface) it allows us to create very sensitive detectors that will be very resistant to noise. Moreover, in the future this technology may allow for embedding electronic circuits in bioengineered organs, improving our monitoring capabilities.”

Read Report

Guan YS, Ershad F, Rao Z, Ke Z, Curty da Costa E, Xiang Q, Lu Y, Wang X, Mei J, Vanderslice P, Hochman-Mendez C, Yu C. Elastic electronics based on micromesh-structured rubbery semiconductor films. Nat Electron 2022;5:881-892. https://doi.org/10.1038/s41928-022-00874-z.

Related Story

New method can scale, simplify manufacture of stretchy semiconductors

Penn State University

November 29, 2022

By Mariah R. Lucas